Let us give shape to your ideas!

We manufacture carbon brush holders, filters, switches, and contact units on production equipment with a capacity of between 5000 and 10 million units per year. Plastic injection moulding takes place in our one and two-component injection moulding workshop, where over 700 different sizes of product are created.

Our engineering team can help you in the following areas:

- Product and process development with cost optimization

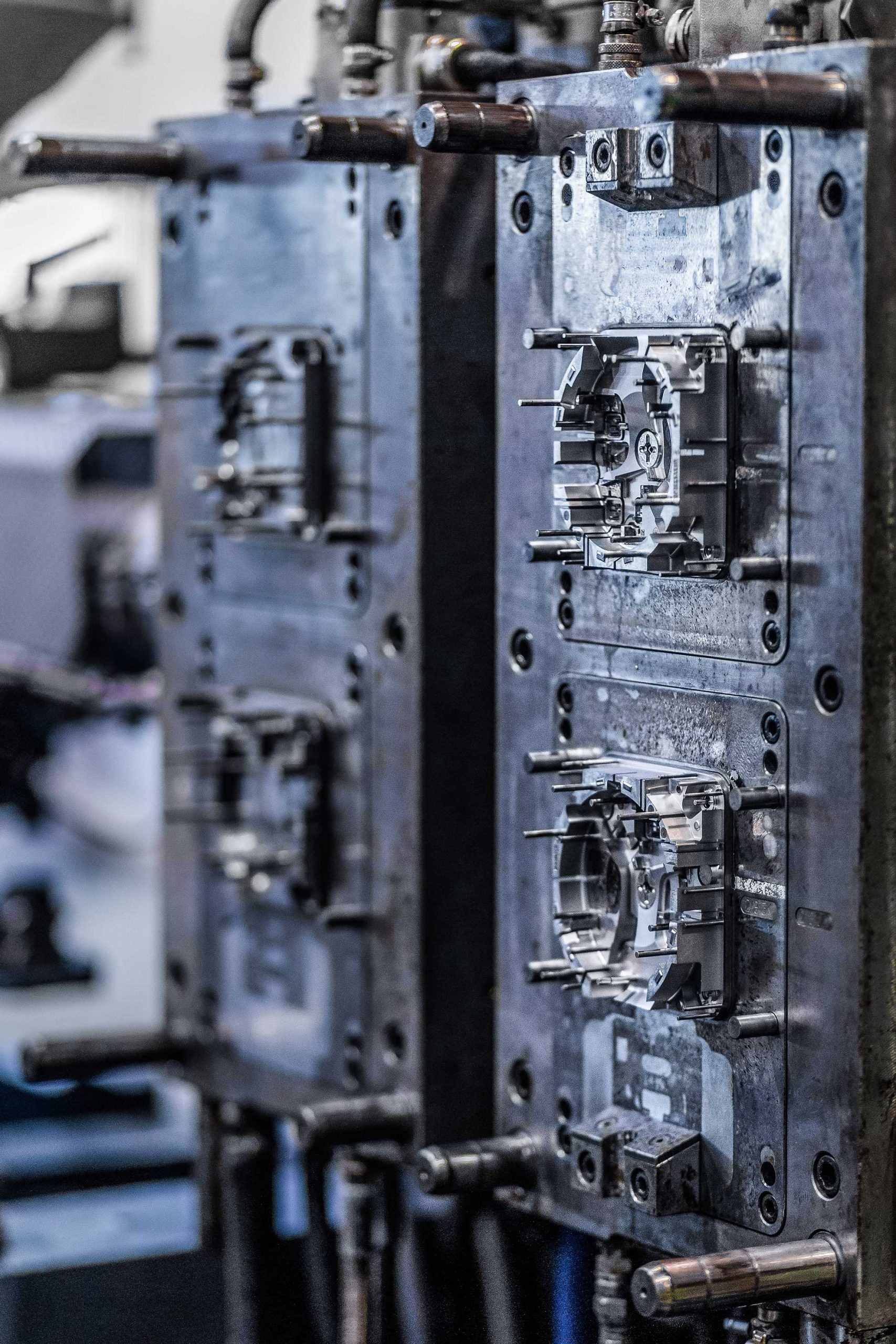

- Mould making and optimal injection mould design

- Injection moulding tools up to 16 cavities!

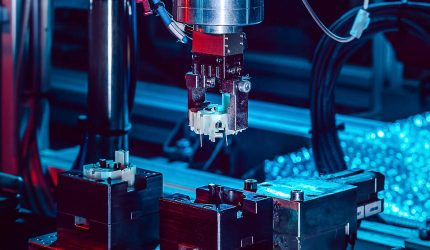

- Filling simulation and calculation

- Moldflow-simulation

- CAD design

Our injection moulding competencies:

- Processing of any thermoplastic material at temperatures of up to 500 °C

- MuCell-technology

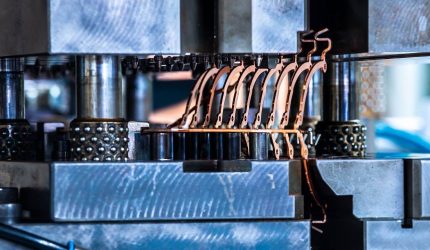

- Overmoulding of stamped or bent inserts and lead frames

- Overmolding of electronic components and soldered subassemblies

- Silicone moulding

- Composite parts made of metal and any thermoplastic material

- Wall thicknesses of 0.3–5.0 mm and manufacturing tolerances up to 0.03 mm