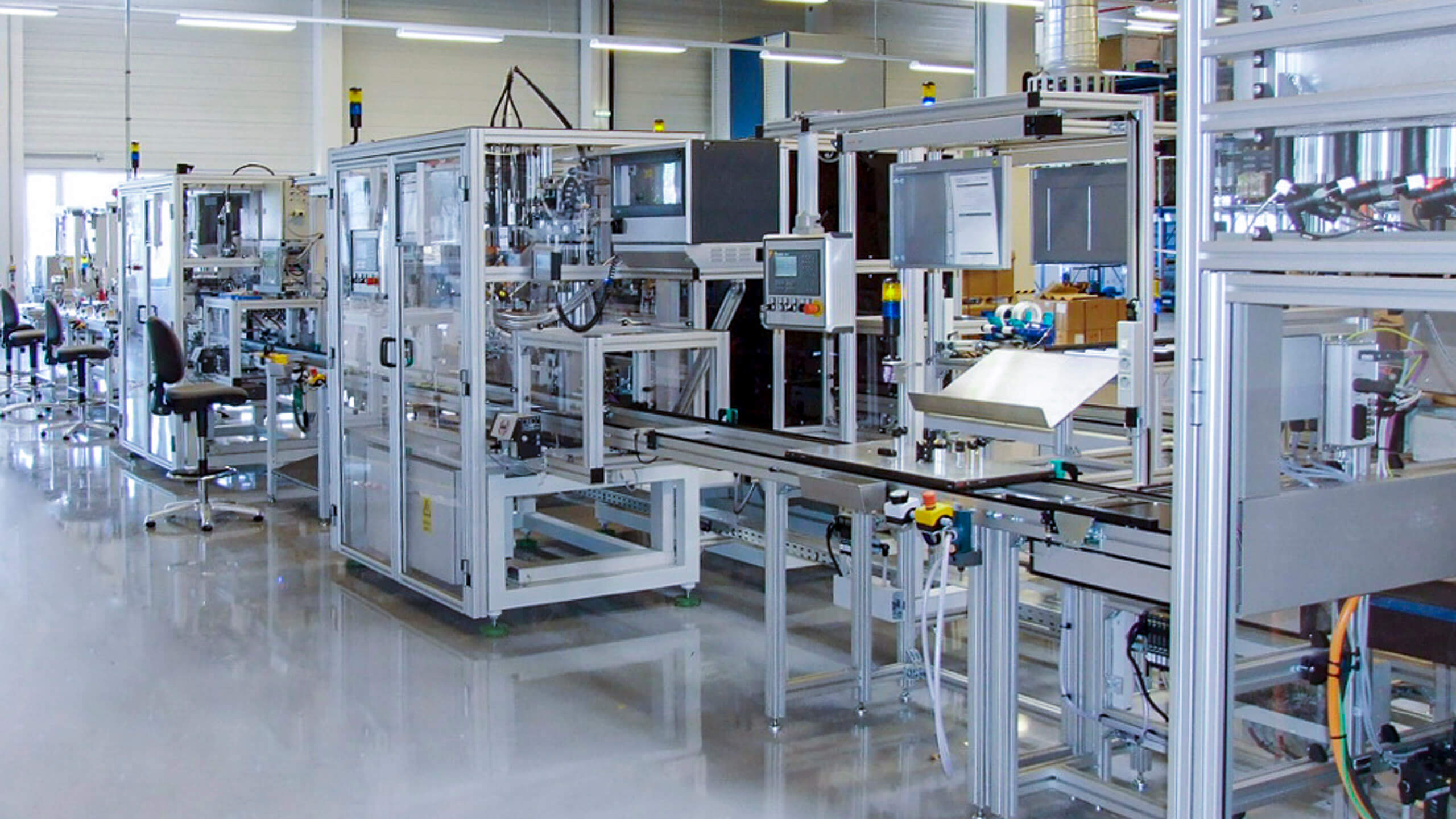

We have decades of experience in constructing single-purpose machines. Our product range includes partially and fully-automated systems as well as manual production systems. Our goal is to optimize our customers’ production, to increase efficiency and profitability, and thus create a competitive advantage.

In order to satisfy their requirements perfectly, we engage in continuous consultation with our customers and implement the knowledge we have gained in our product range. We consider the impeccable quality of all components to be essential and we ensure this through our in-house planning and execution processes.

Individual solutions are unlimited. There are countless possibilities for production systems that can be freely combined: automated stations, automated production lines, controlled assembly lines, circular tables, conveyor systems, pressing stations, screwing stations, manipulators, single-part magazines, pick-and-place palletizing systems, U-cells, welding and soldering systems, and test stations.

Depending on the task, the above list can also be expanded with manual production systems suitable for production processes that are difficult or even impossible to automate.

Our assembly systems will support you in process optimization. Send us the plans and designs for your desired system and we will develop a tailor-made solution for you. By using lifts, lifting and rotating devices, material racks, and conveyor systems on our machine frames, stations, and tables, we can fulfil your requirements down to the very last detail.

Please contact us to arrange an on-site visit, following which we will be able to give you our expert advice.